Facade Systems

Anvil Metal Cladding Systems

In partnership with:

Anvil Metal Cladding Systems

Anvil is a range of aluminium rainscreen cladding panels that are attached using framing systems to the outer skin of the building construction. Anvil metal cladding panels can be manufactured to size and fabricated using aluminium, stainless steel, copper, corten steel and zinc metals, which can be supplied in either an anodised, painted or mill finish.

The systems available include pressed plank secret fix (PPSF), recessed joint fix (RJF), interlocking multi plane (IMP) and secret fix landscape and portrait (SFL/P).

We work with a number of high-quality fabricators across the UK, which enables us to have access to a variety of tested systems and offer our customers more flexibility with regards to availability and capacity. Working with architects, contractors and installers we can help create specifications suitable for the needs of your project.

Each system can be supplied in a variety of colours and finishes in A1 and A2 fire-tested materials, supplied with manufacturer's warranties and CWCT testing certificates where applicable.

Systems

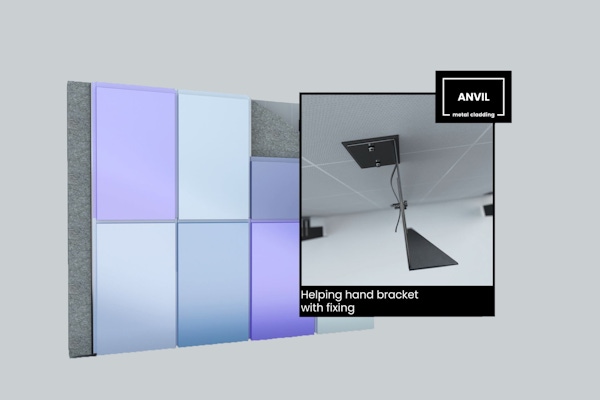

Interlocking Multi Plane (IMP)

Anvil metal cladding is available using an interlocking multi plane (IMP) system with a secret fix joint. The secret fix joint means there are no visible fixings, providing a precise and uniform finish to the facade.

To suit individual design requirements, the IMP panel system can be utilised to create a range of facade patterns. The system can employ a mix of wedge-shaped and variable depth cassettes, allowing the creation of varying panel configurations and geometric effects. These cassettes can then be laid in a multi-directional fashion, allowing the construction of highly creative aesthetic details.

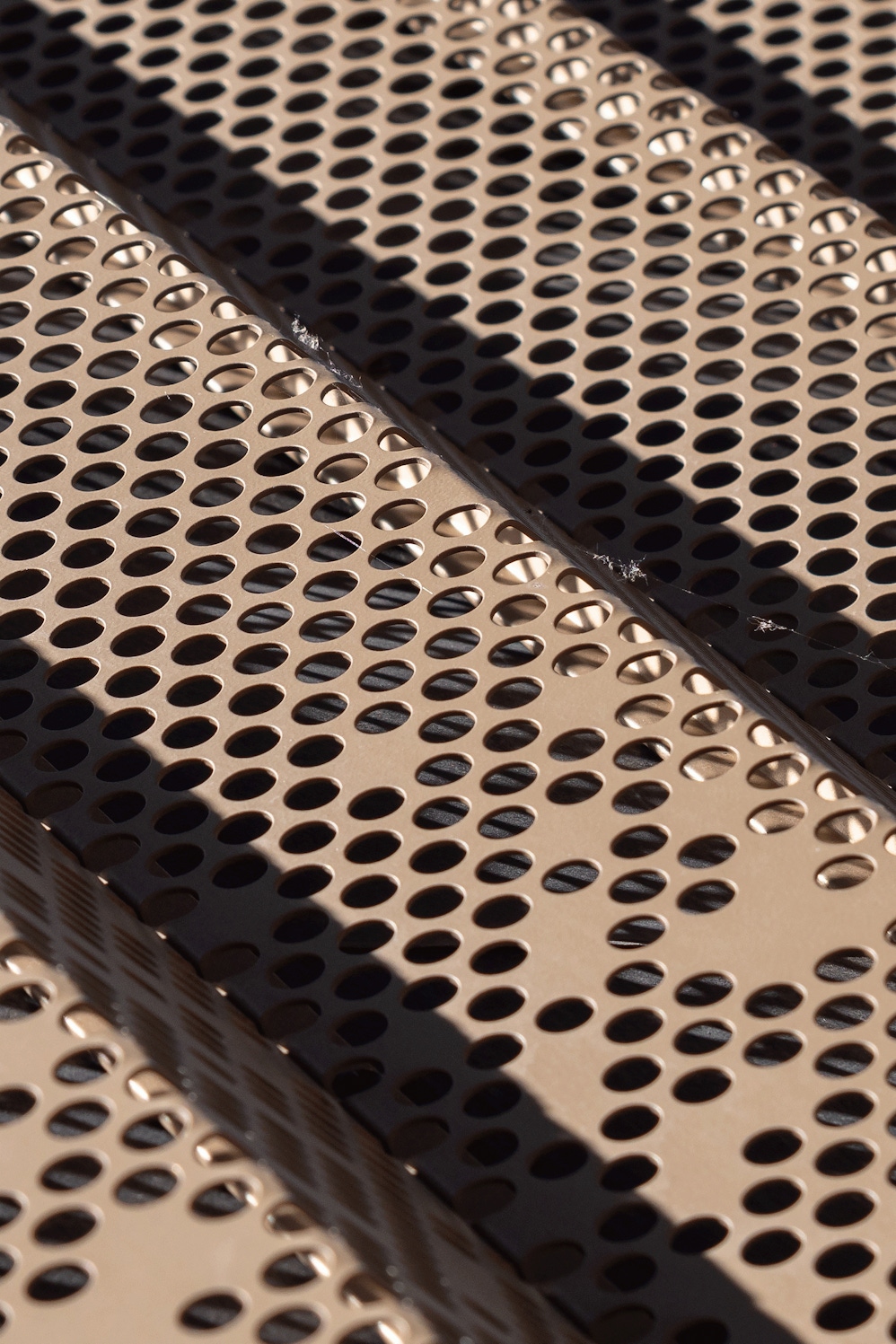

It is possible to perforate the faces of the cassettes, providing another means of generating unique and decorative visual effects on the facade with perforated aluminium panels.

The IMP system is available with a PPC, natural metal, or anodised finish. For samples, further details regarding the colours/finishes available, or technical details, please contact us.

Recessed Joint Fix (RJF)

Anvil metal cladding is available using a semi-concealed recessed joint fixed (RJF) system with an overlapping joint. To provide a consistent finish to the facade, coloured fixings are available to match the aluminium panels.

It is also possible to perforate the faces of the cassettes, providing the option to generate unique and decorative visual effects. The panels can also be laid in a multi-directional, staggered pattern, allowing the construction of a highly creative aesthetic to suit individual project designs. Available in panel sizes up to 1.3m x 3.8m. The standard joint width for this system is 20mm.

The RJF system is available with a PPC, anodised, natural metal or A1 pre-coated finish. For samples, further details regarding the colours/finishes available or technical details, please contact us.

Secret Fix Landscape/Portrait (SFL1/SFP1)

Anvil metal cladding is available using a secret fixed joint system with either a landscape (SFL) or portrait (SFP) profile. The concealed joint means there are no visible fixings, providing a precise and uniform finish to the facade. Comprising of secret hook-on cassettes, this system is available in variable sizes, allowing design freedom to create a desired pattern/effect using the multi-variant cassette formats. Well suited to over-cladding existing facade structures.

Available in panel sizes up to 1.3m x 3.8m. The minimum joint width for this system is 10mm.

The secret fix system is available with a PPC, anodised or natural metal finish. For samples, further details regarding the colours/finishes available or technical details, please contact us.

Pressed Plank Secret Fix (PPSF)

Anvil metal cladding is also available using a pressed plank secret fix (PPSF) system which utilises a secret clip fix joint on to an aluminium support framework, providing an aesthetically clean finish with no visible fixings.

Similar to the recessed and interlocking systems, the pressed planks can be laid horizontally, vertically or in a multi-directional fashion, allowing the construction of unique and imaginative project designs. It is also possible to perforate the faces of the cassettes, providing another means of generating decorative visual effects on the facade.

Planks are available in face widths of 100 – 400mm and in lengths of up to 6m. To create the look of longer lengths, the system can be utilised with butt joints. The PPSF system is also available with a PPC, anodised, natural metal or pre-coated finish. For samples, further details regarding the colours/finishes available or technical details, please contact us.

Perforated Metal Panels

Perforated metal panels are produced by punching holes of different shapes and sizes into cold sheets of metal to create various patterns. The amount and size of the perforations are a critical factor for consideration in the design process. We can supply round, square or special-shaped perforated systems as well as bespoke perforated or embossed patterns to suit your project design requirements.

A range of tools can be utilised alongside punching machines to create different perforations or emboss patterns, that can be either convex or concave. The material work hardening properties that result from the embossing process create a much stronger panel solution. As well as the aesthetic properties, perforated panel systems are an effective method of satisfying ventilation and solar shading requirements.

Our team can provide technical advice and guidance to assist you in selecting the appropriate format of perforated metal panel, such as advice regarding acoustics, light transmission and ventilation.

Colours and Finishes

We also offer an extensive portfolio of over 180 polyester powder coated (PPC) RAL colours, available in either a matt, satin or gloss finish as well as a range of anodised and anodic-look PPC finishes – a cost-effective alternative to the anodised finishes, that create the visual of an anodised surface.

For an affordable solution to natural materials like stone, we provide a range of PPC mineral textures. As an alternative, we provide a range of natural metal finishes including bronze, Corten and copper, as well as an additional PPC metal-look and metallic range.

All of the PPC colour ranges are A2 fire rated (tested to EN13501-1). For some examples of colours available, please see our gallery, explore our product selector or contact our team for more options.

Resources

Be inspired

More facade systems

Visit our showrooms

In partnership with:

Speak to our team

To speak to one of our team, call us on 0203 794 9377 or email enquiries@taylor.maxwell.co.uk

Contact our team